This is one way to install new braids/wire. I’m certain there are many variations.

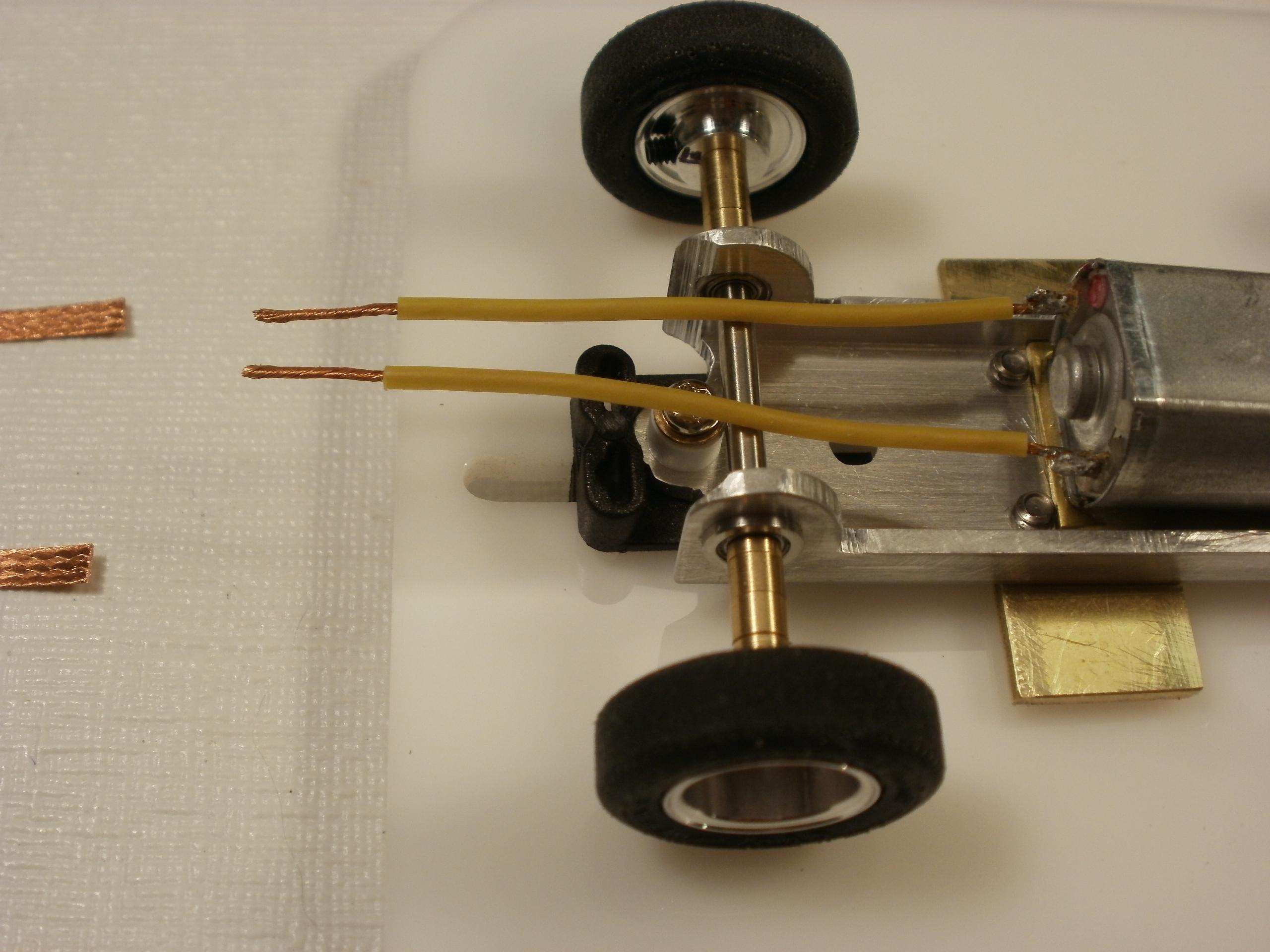

First, tin the motor.

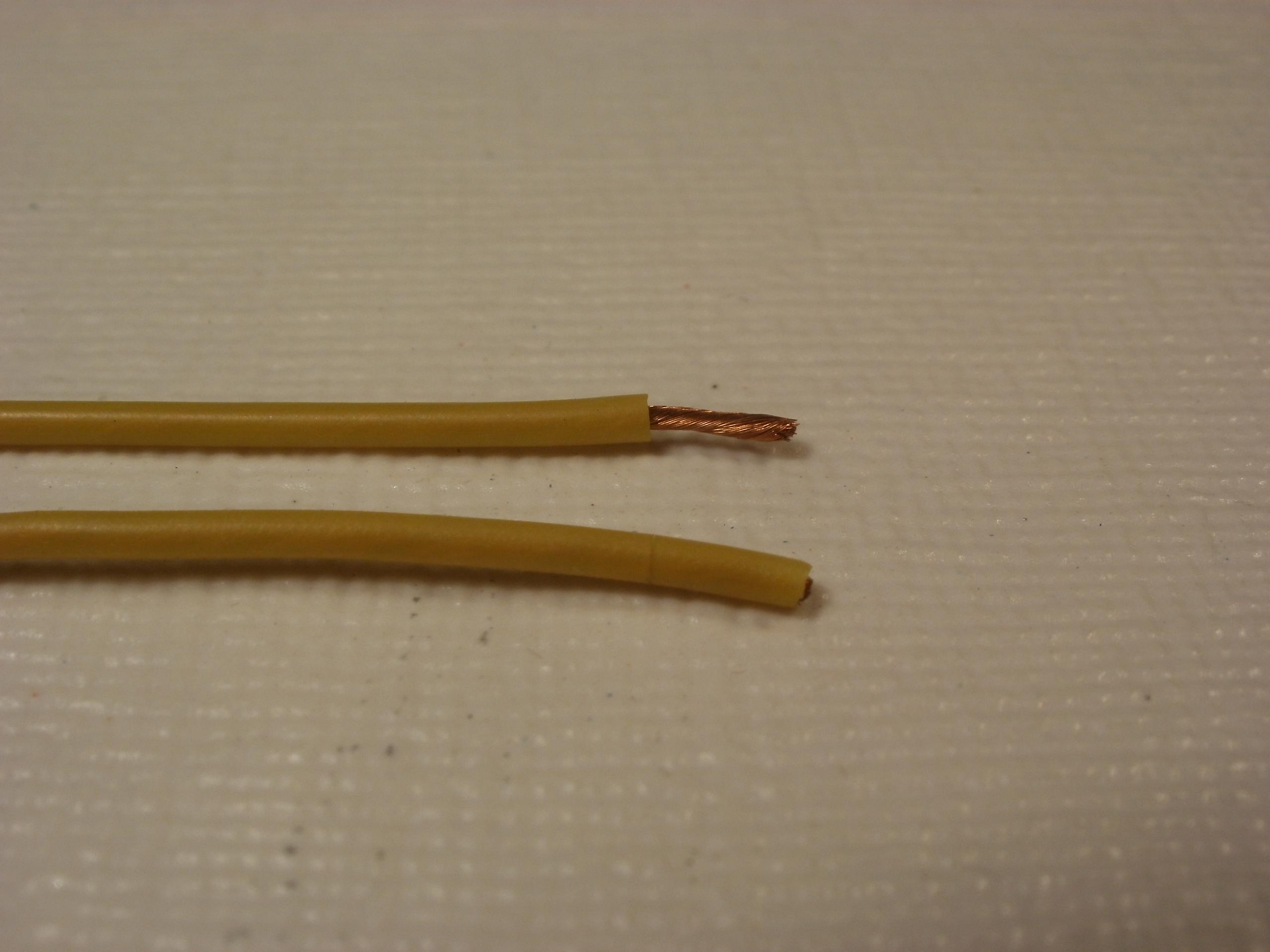

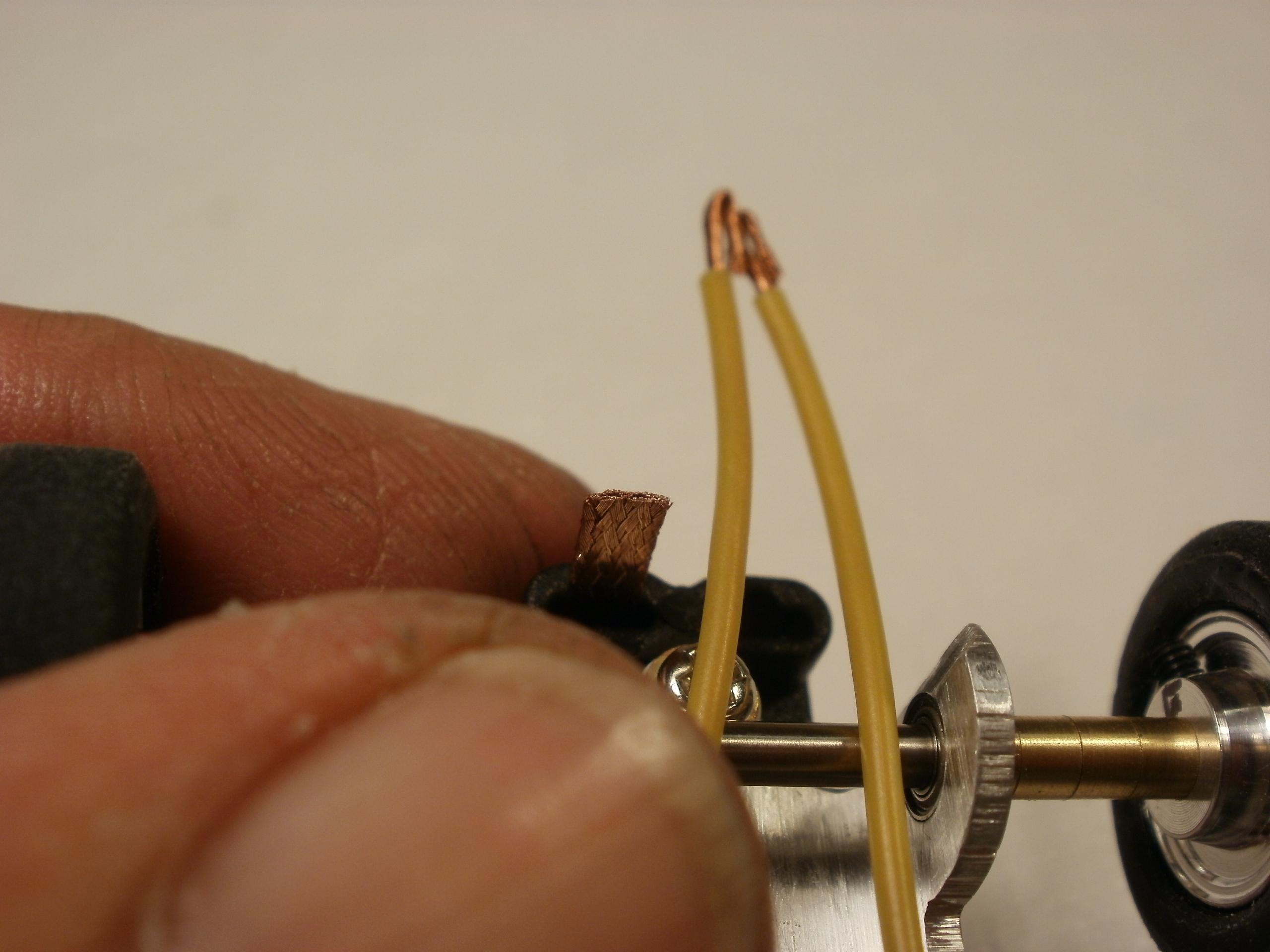

I gently roll the wire with a razor knife to barely cut a line into the shielding so as not to cut the core. The shielding pulls off with a small tug without taking any precious wire with it. You want the entire copper core if you can.

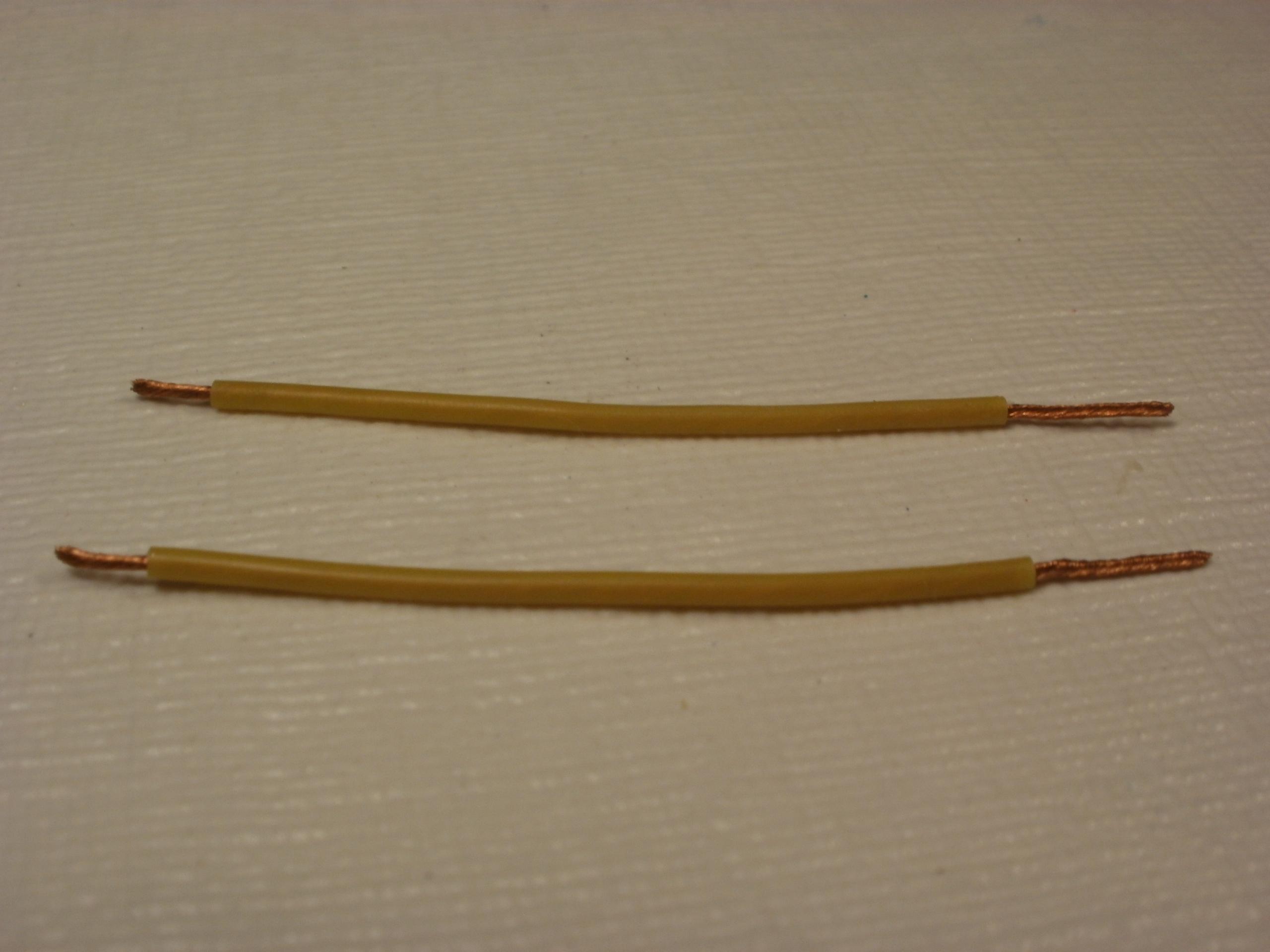

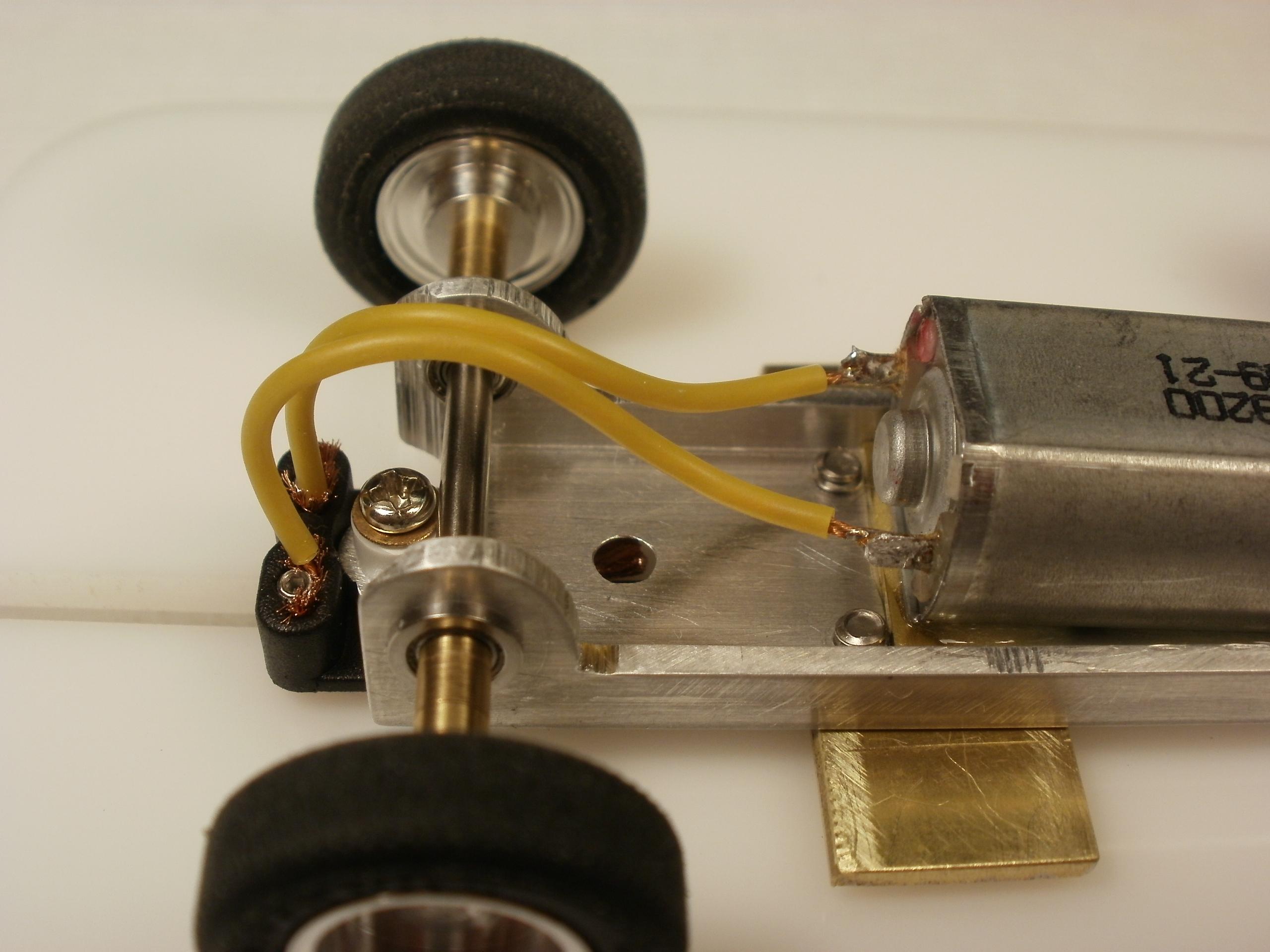

The wires are cut to length to go past the guide by about 20mm. 4mm of the shielding is stripped on the motor end and about 8mm from the guide end. The loose core is twisted to prevent fraying.

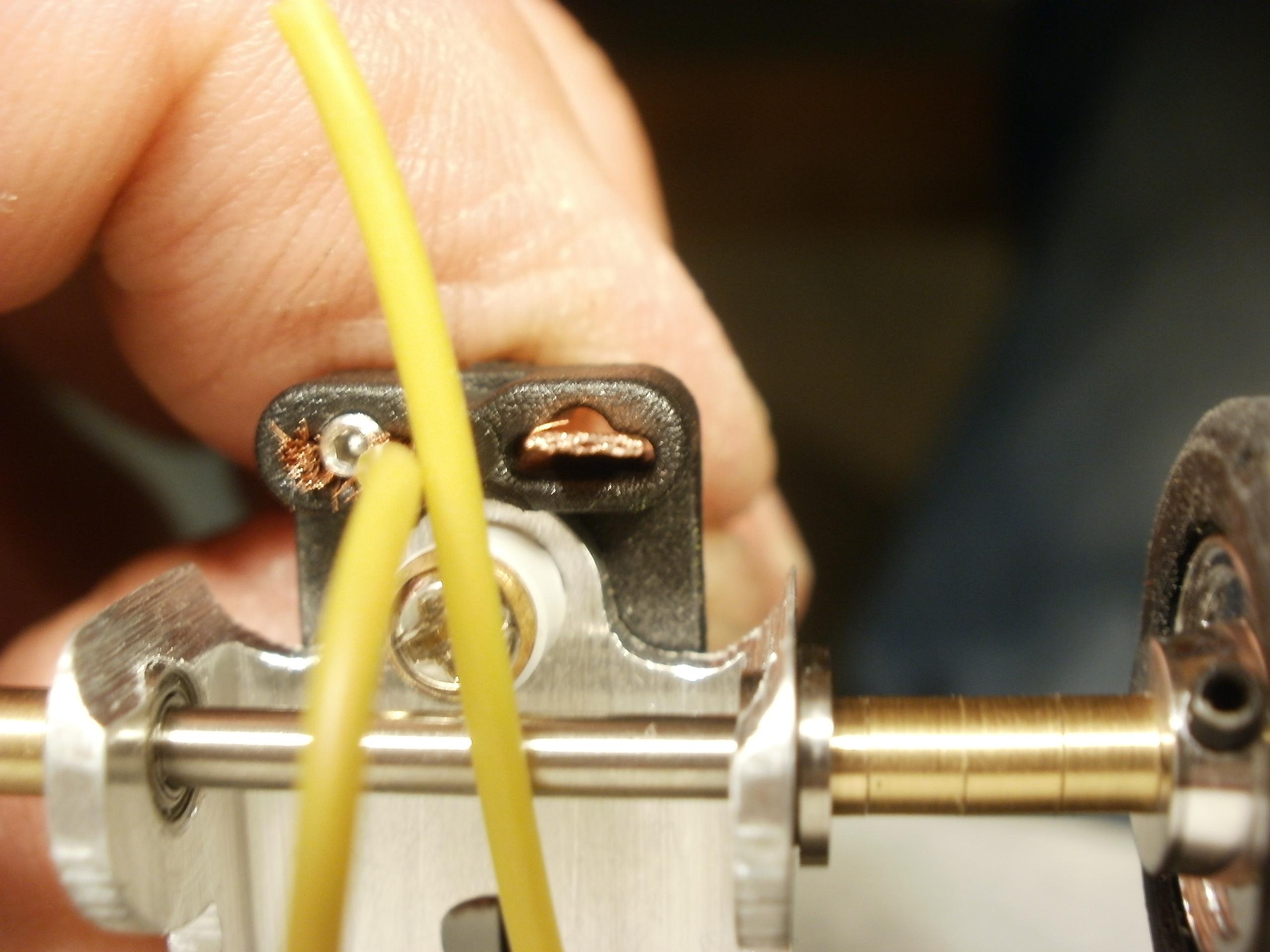

The small ends are tinned, and soldered to the motor.

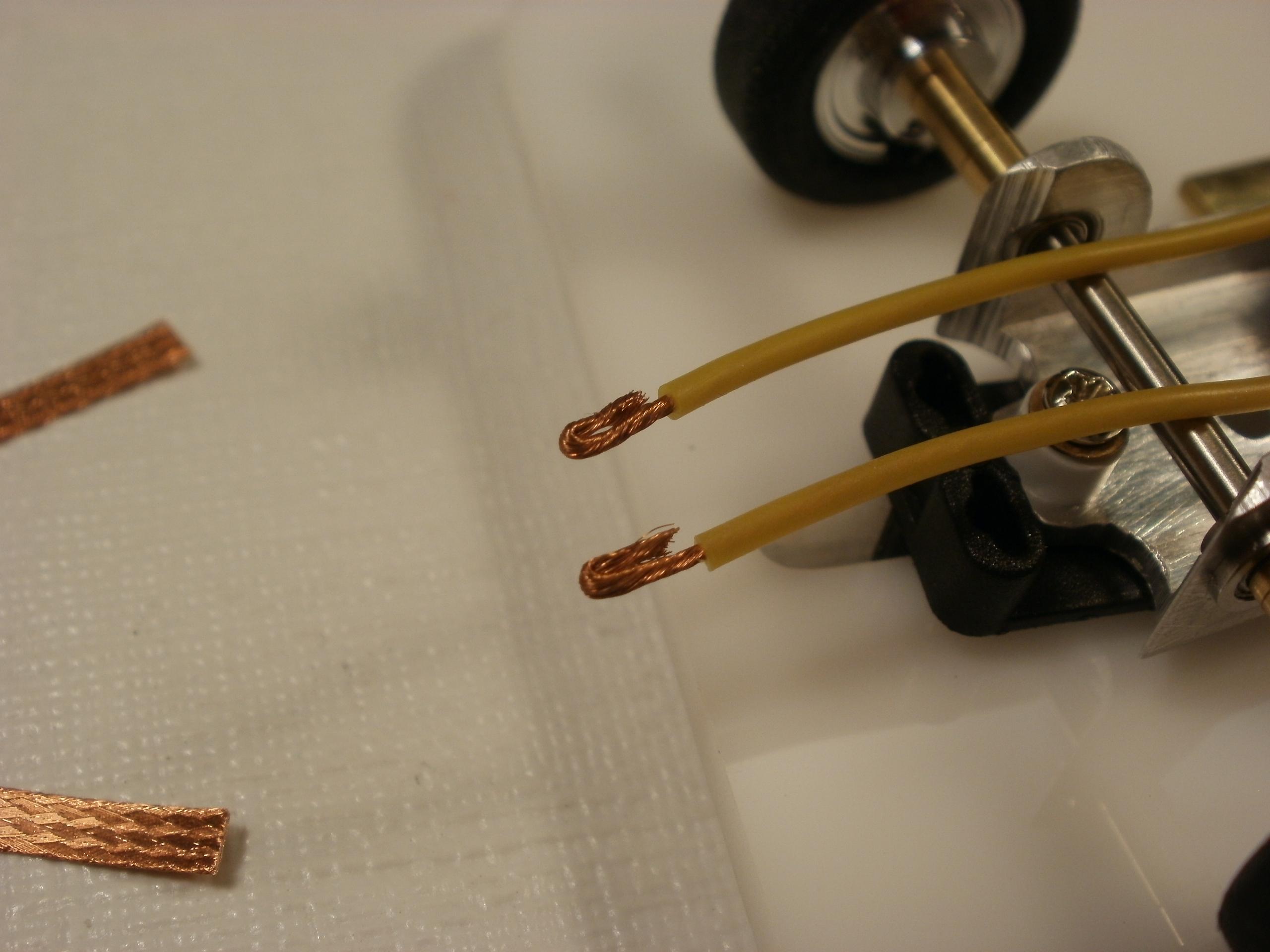

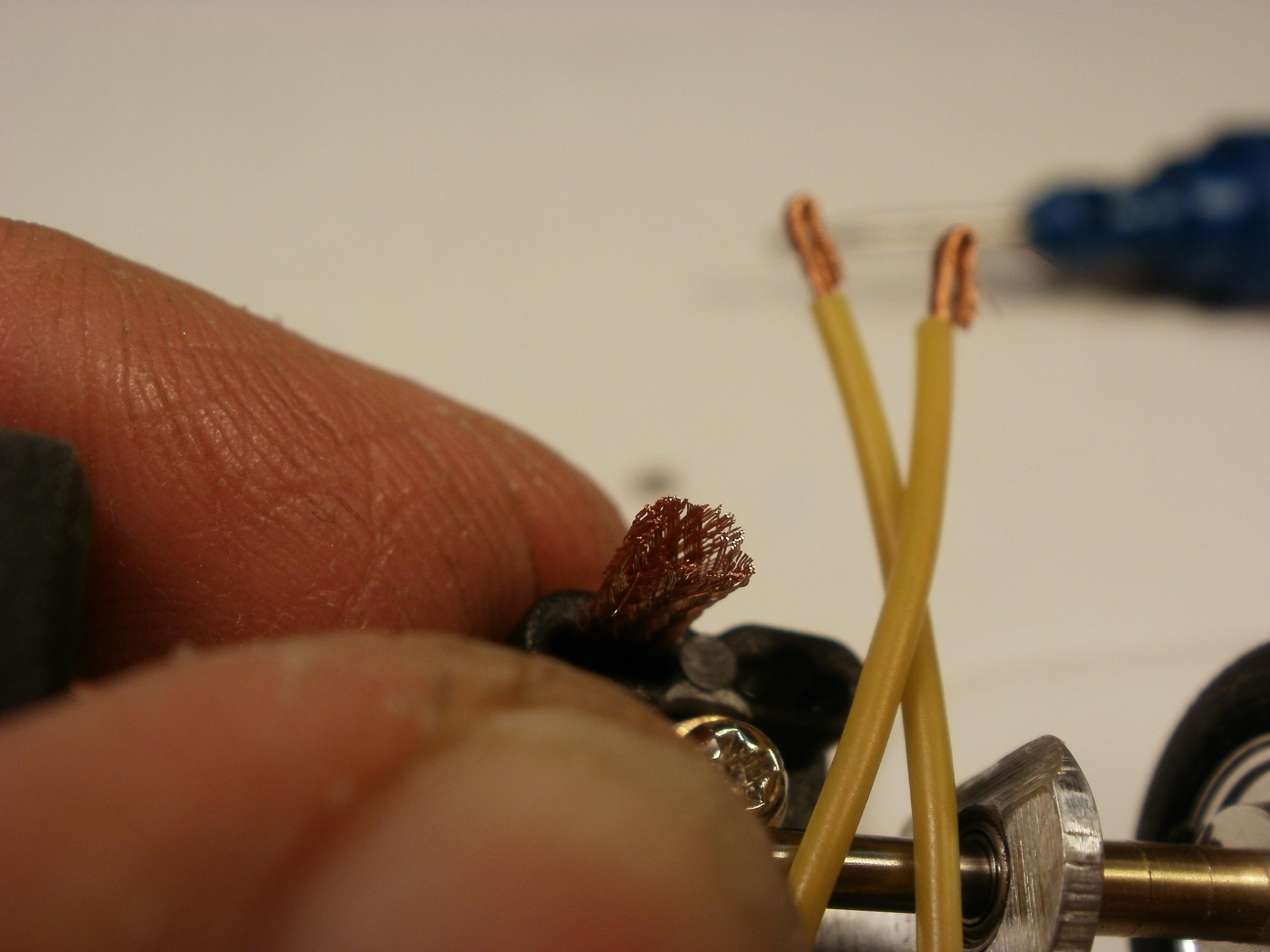

The long end that goes into the braid is folded in half to help the set-screw grip the wire. It also lessons the strain that might prematurely fatigue the wire.

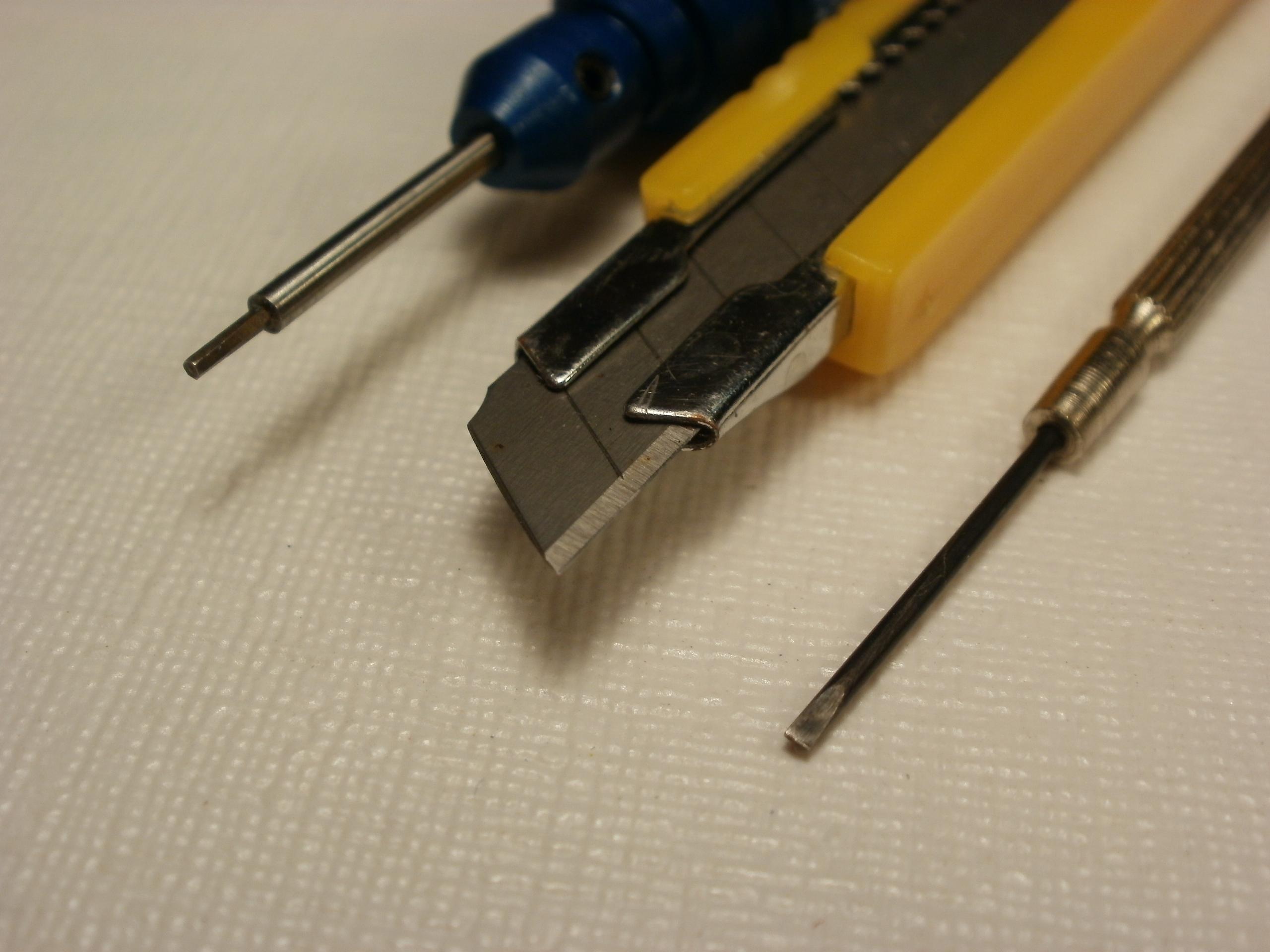

Have the following tools ready to go. Small razor/knife, 2mm set-screw pre-installed in the driver, and a very small flat-screw driver.

Slide the braid through the guide. Use the knife to open the braid in the center just enough to fit the small screw-driver.

Open the braid enough so the wire can easily fit.

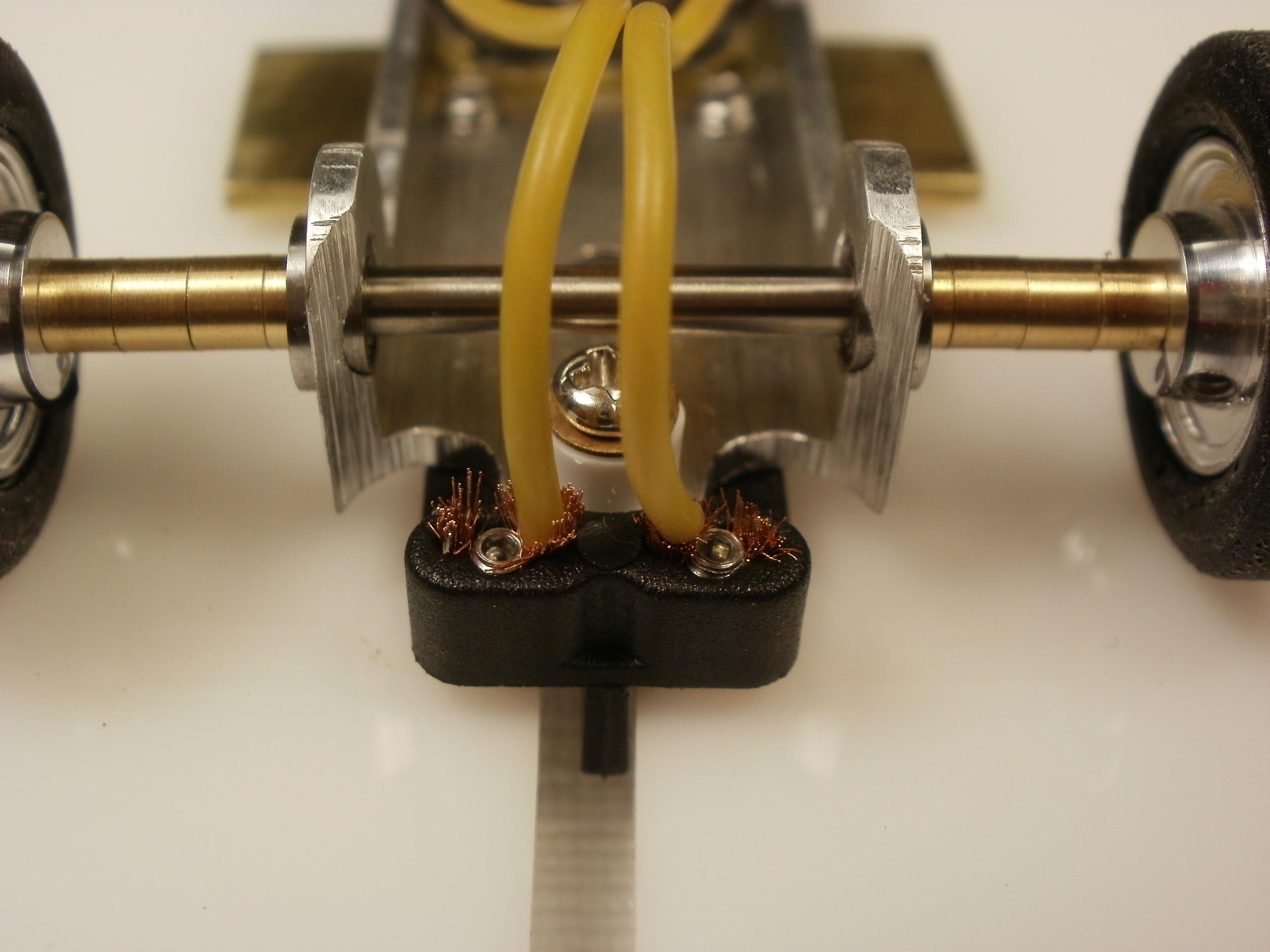

Slip the folded wire into the braid until the shield meets the braid. Make sure the wire is closest to the inside, or center of the guide. Then slid it into the guide and install the 2mm set-screw outside the braid, in the center hole.

Repeat on the opposite side keeping the wire close to the inside again.

Keeping the wires near the inside of the guide keeps the total movement of the wire to a minimum. It has less fatigue on the wire making it last longer. Less strain on twisting the guide helps the car slip through corners.

Thanks for looking.

Ken