Time to figure out something of an infield style layout. Some key considerations for me:

- Curbs, transitions and everything fixed to the on road track surface must have a transition or height of no more than 2mm so that these hard body models can manage without snagging them (or tearing them up);

- Barriers will be EVA (Ethylene-Vinyl Acetate Copolymer) foam preferably 3 oz. weight (softest) and between 3/8″ – 1/4″ (or 12mm) in height – no taller – to avoid snagging rear wings or any other fragile body detail;

- Barriers must be fixed to the borders or track surface with some sort of detachable system so that they may be removed, added whenever the infield layout changes or simply break away in the case of a severe impact. Circular holes cut to fit a heavy object such as a hockey puck placed inside the barrier or magnets recessed into the foam attracted to thin steel plates fixed to the track are two simple options that I’ll try; I like the magnets because they are small and can be hidden in scale style narrow walls or ‘Jersey’ barriers… it is important that these barriers lie flat so that the models don’t submarine – which not only defeats their purpose but also causes lots of damage to the fragile antennae, mirrors, wipers, etc.

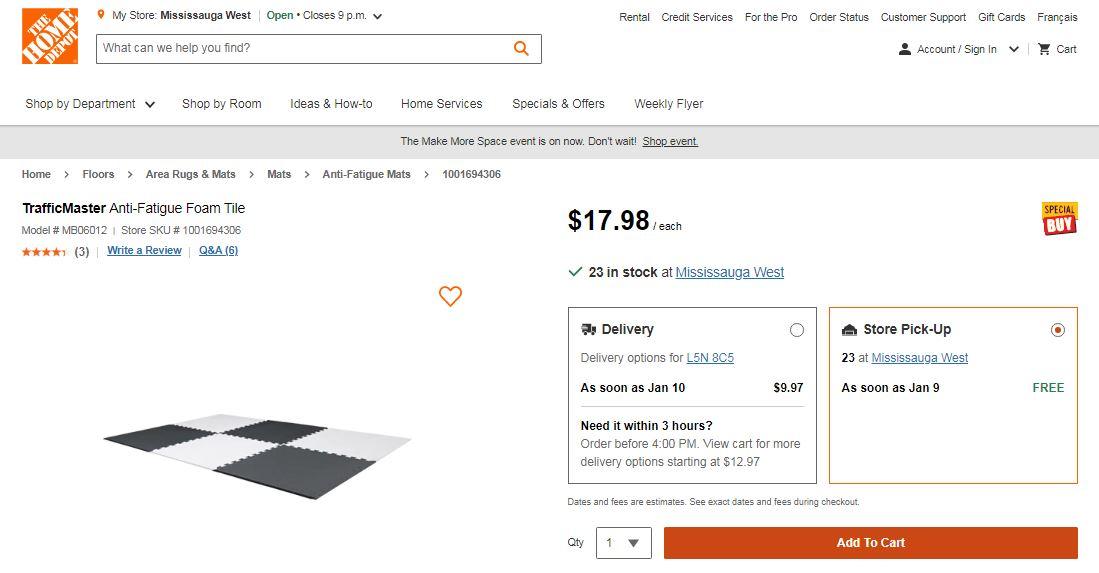

I picked up a pack of TrafficMaster (Home Depot Brand) EVA foam floor tiles (12mm thick) from Home Depot for $18 for six – light grey and dark grey – 3 of each covering 24 sq. ft. – to cut up into barriers. EVA foam tiles can be cut cleanly (and channeled) on your table saw or band saw BTW…

Painting the EVA foam works but it will rub off… something to keep in mind if you plan to use EVA foam tiles as a racing surface. This foam doesn’t give much grip unless it is damp – another thing to keep in mind…

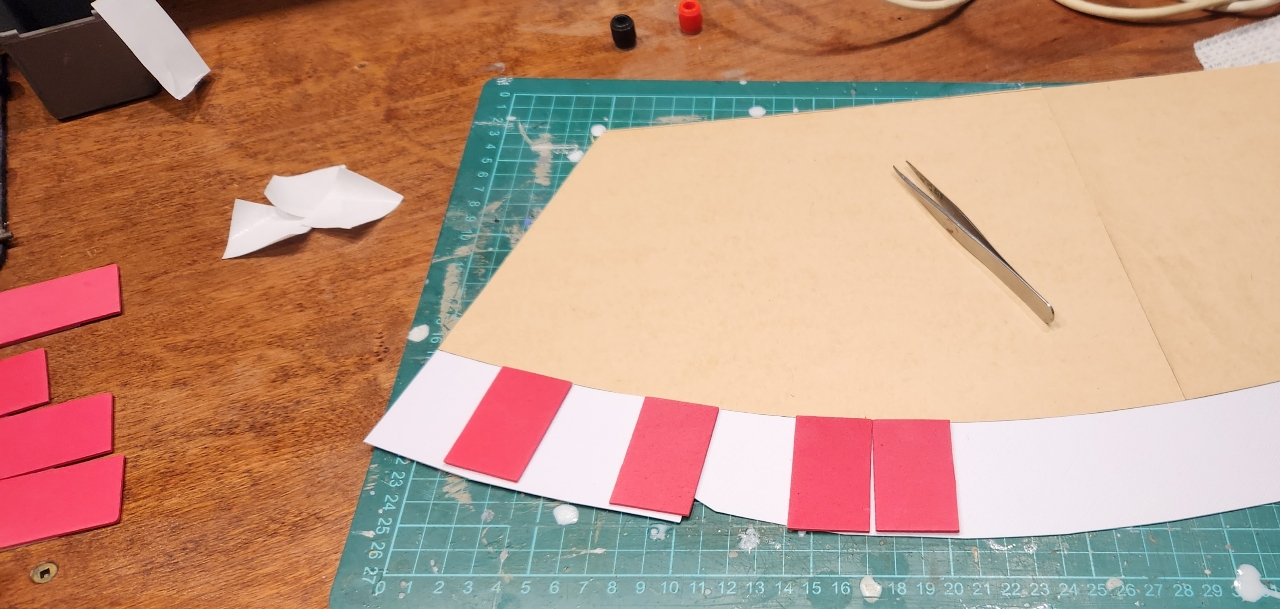

Let’s make some curbs and infield sections using white cardboard as the base and fixing 2mm EVA red foam squares (from the dollar store) on top. We’ll eventually fix these curbs to the track surface using Scotch brand double sided carpet tape (the indoor version works well for smooth surfaces but for rough or painted surfaces the outdoor version is much better but almost double the price):

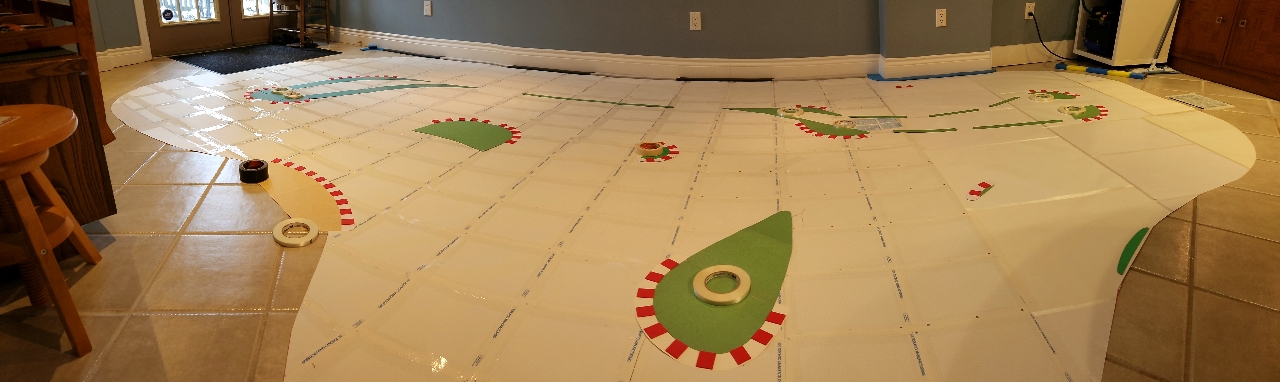

For now we’ll simply place these loose around the unpainted floor plan to test – in various sizes and radii. I like the straight up against the back wall with a decreasing radius 1st corner (going counter clockwise).

Time to paint the paper – after stretching it out and fixing it to the floor using duct tape – using an ultra flat primer… then re-stretch the paper after the paint dried… and tape down all of the edges so that the transition for cars running wide is nominal – and more importantly without the possibility of submarining when re entering the track.

Now lets fix the curbs and infield cardboard sections to the painted paper racing surface using Scotch brand outdoor double sided carpet tape.

Notice that I added some sandpaper to a few portions of the infield… let’s test that out too… I’m thinking 2 or 3″ wide sandpaper edges around the outside of the layout to improve the grip of any models sliding wide… do they provide more grip than the painted surface? Who knows… I think they’ll offer less grip which may be even more realistic… but they look like a gravel runoff without doing anything more… if they flip a car they’ll be removed but that’s why we test…

Time to have some fun!

The remaining ripples in the paper are not a problem for the models to cope with but in any final version of this floor or table layout a thick cardboard underlay or 2.7mm ply will be used. Remember, this is a test layout to sort out what works and what doesn’t… so far so good…

Next up some infield removable raised walls/barriers…

Attachments:

You must be

logged in to view attached files.

The Happy Canadian Scale Modeler!