One of the first lessons Art showed me was how to make independent front wheels. Thank you very kindly Art. I was asked to pass it on.

You can buy independent front axles. But it’s far too easy to make your own.

The ingredients are as follows: Professor Motor axle blanks, Dubro #2 flat washers (hobby store), soldering iron, Lucky Bob’s acid flux, drill, file, and fine rosin-core solder.

I polish both sides of the washer with 2000-grit paper to remove burrs or dirt.

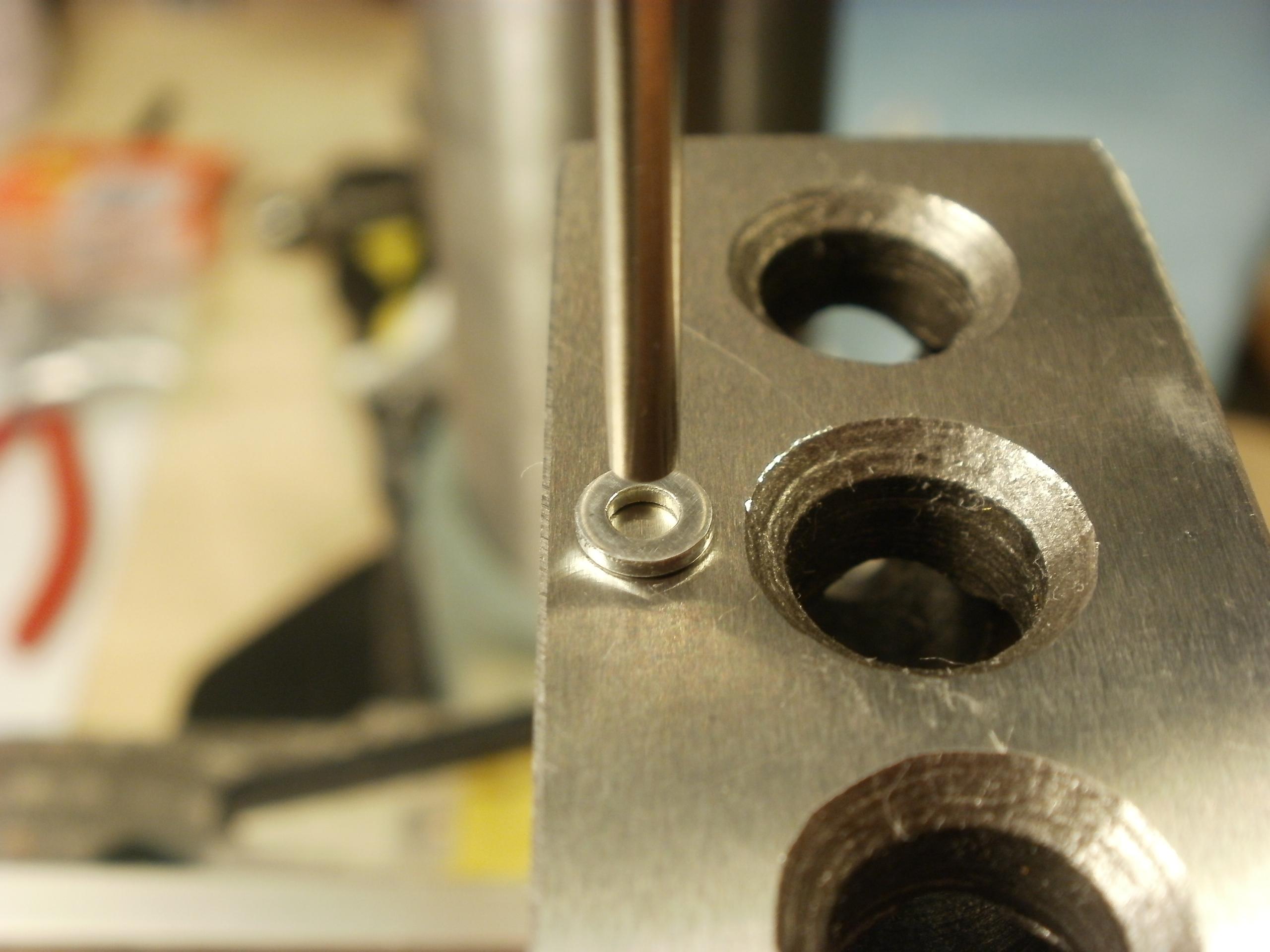

Then I install the axle in the drill press and press the washer on (flat side to the wheel). Some fall off so I discard those. Others won’t go on so I discard those as well. You’ll lose about two out of ten washers. You can also use a small hammer and your eye. However, the washer may not be as true as a drill press.

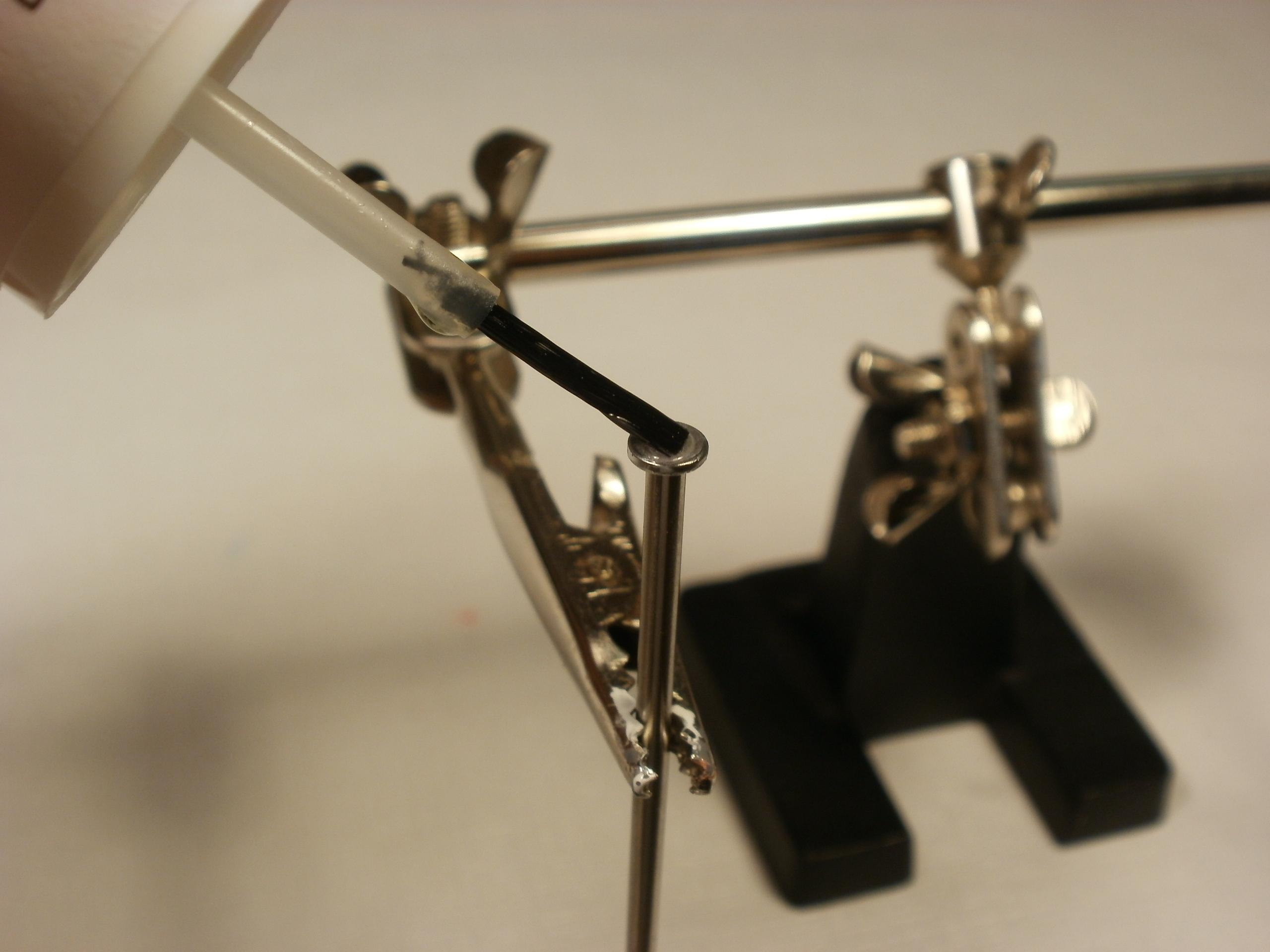

I touch the a little solder to the iron and gently dab it onto the washer without disturbing it. I’m not concerned about the blob of solder on the end of the washer. You’ll see why shortly.

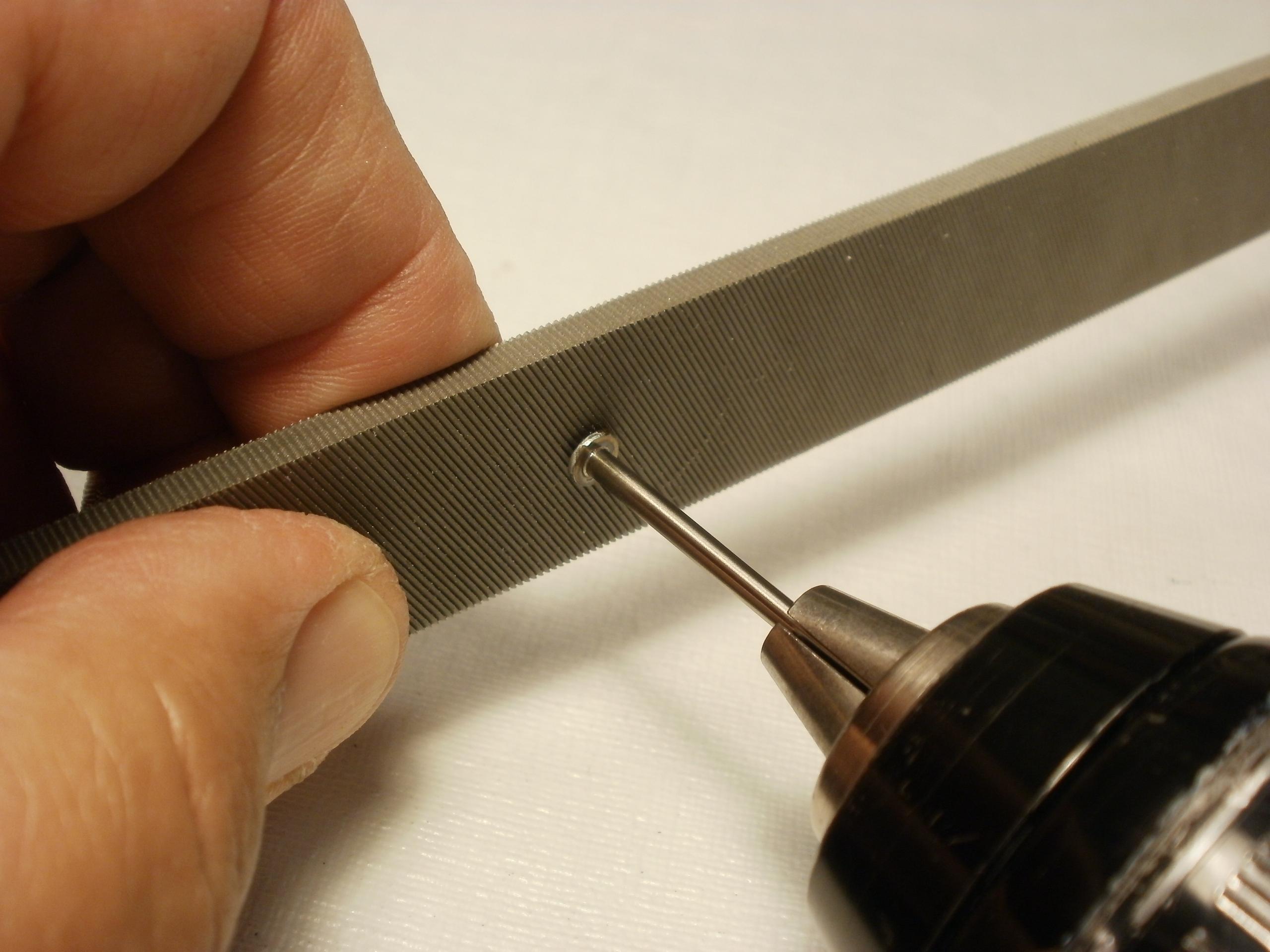

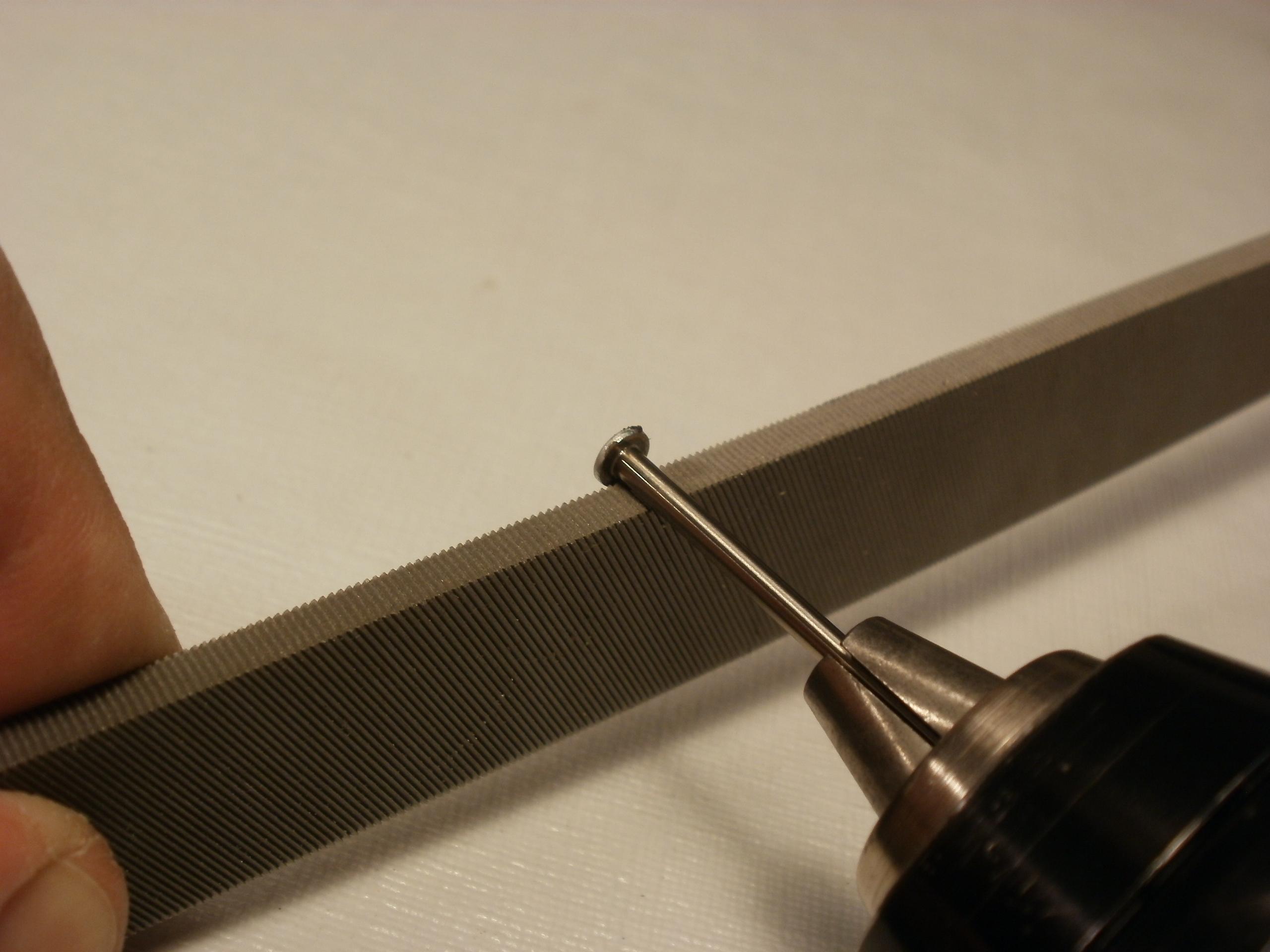

Then I install the axle in a drill. Spin it up and use a file to chew away the extra solder that isn’t needed.

I gently file all three sides of the washer to make it very smooth. Let the drill do the work.

Nice little pile of lead left on the file and work bench. As true as my drill press can get it, and ready to use. Not to mention as thin as the washer itself. Takes about 10-minutes.