From the original Airfix Model Kit:  If you can’t read the fine print here it is:

If you can’t read the fine print here it is:

“Alfa-Romeo, one of the most famous of the Italian car companies and still one of the foremost manufacturers of high performance cars, started in 1907 building the Darracq under licence. After the First World War they introduced their own very successful series of sports and racing cars. The 1933 8C was a development of the ‘Monza’ racer of 1931 which won at Le Mans in 1931, 1932, 1933 and 1934 and this car was beaten into second place in 1935. The low four-seater sports body is typical of its era and the 2,336 c.c. supercharged twin overhead camshaft engine with its eight cylinders in line is also typical of the period. This model is based upon the car owned by the late Mike Hawthorn.”

So after doing a little research I decided that I would model a fantasy period livery in the same colour scheme as this 1:1 survivor (which is an 8c 2300 LM – with the round streamlined lid covering the spare tire(s)). A different version than the one I am building but I do like the extra single windscreens and since there were so many variants of this car that raced I will incorporate a pair of them on my model as well and leave the rest as is, including the uncovered spare tire. Racing number and pilot can be decided later… I do plan to paint the numbers in black.

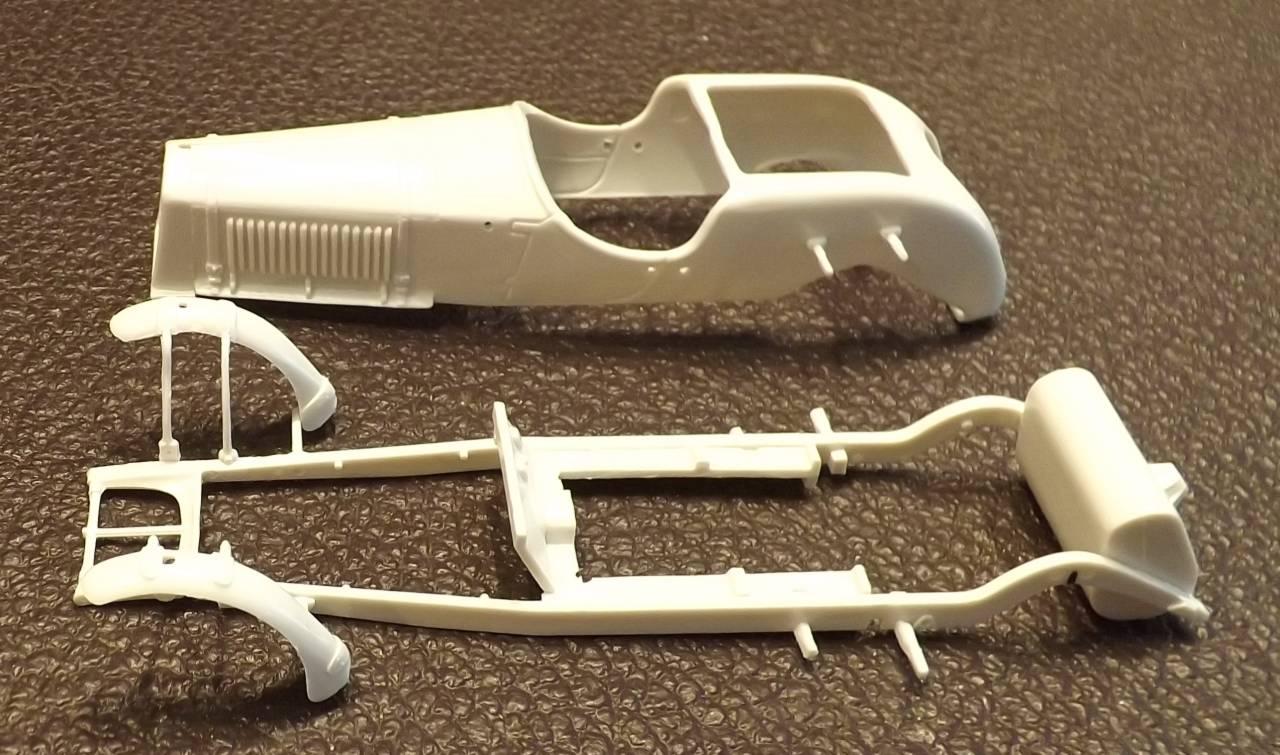

So after looking over everything I decided to start assembling (and welding) what I should in order to be able to sort out the dimensions for the chassis keeping in mind that everything must still be painted – so not everything can be assembled until after paint – and it is first mated to the chassis. I decided to leave the rear fenders separate since I wouldn’t be able to remove the body from the frame with them welded in place. So they along with the headlamps and other various bits will be painted separately and then epoxied together, as will the frame to the body.

So after looking over everything I decided to start assembling (and welding) what I should in order to be able to sort out the dimensions for the chassis keeping in mind that everything must still be painted – so not everything can be assembled until after paint – and it is first mated to the chassis. I decided to leave the rear fenders separate since I wouldn’t be able to remove the body from the frame with them welded in place. So they along with the headlamps and other various bits will be painted separately and then epoxied together, as will the frame to the body.

I cut a channel into the floor to accommodate a mid inline ‘low power’ slim can motor and will decide later if it will be covered with styrene or a flexible piece of metallic plastic sheet. A front motor build would be nice but they are too much work and I would still need to cut away a portion of the interior – so why bother.

Stock frame/suspension pieces such as leaf springs will be added to the frame or chassis after the chassis is built. Front axle/assembly will be determined on the fly as I build the chassis – I may use independent pins for each front wheel but we’ll see.

In any event I plan to use and incorporate the following parts into this build:

- BWMS050 motor w/10t true pitch pinion & 23t slot.it crown;

- Slot.It round ‘self centering’ bushings with PM axles & spacers/washers (I like the very small size of these bushings);

- Scalextric ‘stock’ round guide with quick change plate & Slot.It braid;

- DArt wheels, tires & inserts plus DArt windscreens & pilot; and

- Various K&B brass stock & wire.

I was thinking about adding LED head and tail lights but that might be too ambitious right now – hopefully there is plenty of time in the future…

Next Step: Building the Chassis (stay tuned…)

The Happy Canadian Scale Modeler!