› Forums › Slot Car Paddock › Slot Car Resources › Historical 1:1 › Just for fun

Tagged: Aside from light weight, enabling coachbuilders to quickly construct innovative body shapes., the superleggera construction system allows great design and manufacturing flexibility

- This topic has 7 replies, 3 voices, and was last updated 6 years ago by

MiA.

MiA.

-

CreatorTopic

-

November 22, 2017 at 7:47 pm #4911

So, just for fun, what is this type of construction called? Who developed it? Who used it?

Bonus marks for major benefits and major drawbacks. More bonus marks for how some of these drawbacks were mitigated to some extent.

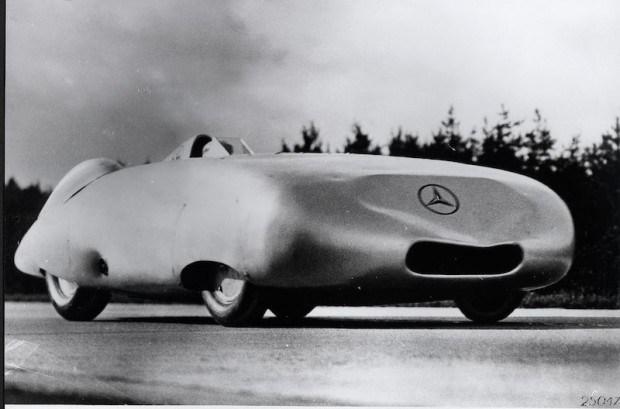

And a guess at which car is in the photo above.

-

CreatorTopic

-

AuthorReplies

-

-

November 22, 2017 at 10:20 pm #4913

ok I’ll take a guess

Tubular spaceframe.

Looks like a Merc or Auto Union streamliner land speed record car.

It must be an Alfa because I know you.

Benefits – light weight drawbacks – fragile and flexible

-

November 23, 2017 at 9:19 am #4915

This is a great idea! Go Bill Go! :yahoo: I love the construction – what a beautiful and sleek looking frame!

The Happy Canadian Scale Modeler!

-

November 23, 2017 at 3:20 pm #4918

Excellent Bill!

And I presume that Art already knows most of the answers since the photo showed up beside an event poster from whence I borrowed it.!!

So:

1. It is not a tubular spaceframe. Some interesting differences between the two that would be worthwhile going into after this little diversion.

2. It is not an Alfa, however in 1937 this achingly beautiful Alfa did use this system and may have been the 1st car to do so after the system was patented. And thanks for giving me an opening to show it!!

3. Certainly some of the benefits and drawbacks are spot on.

What a lucky devil that driver is!!

-

November 28, 2017 at 12:43 pm #5037

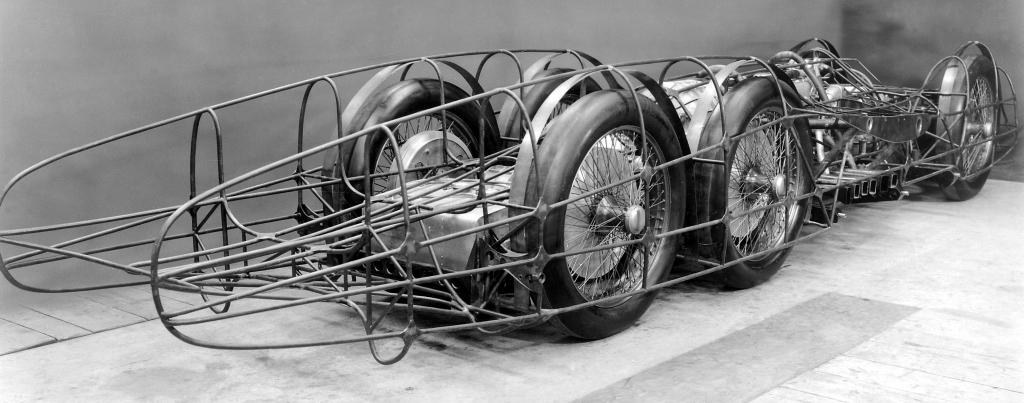

Since inquiring minds wanted to know…

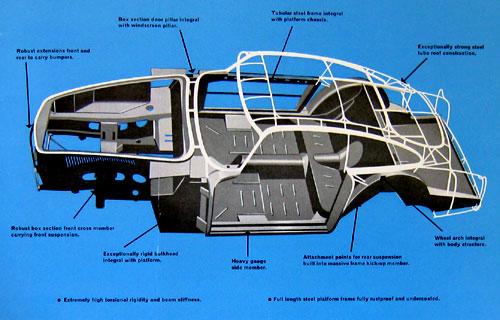

1. The construction method is “Superleggera” literally ‘super light’. Patented by Carrozzeria Touring in 1936, the superleggera system consists of a structural framework of small-diameter steel tubes that conform to an automobile body’s shape and are covered by thin alloy body panels that may somewhat strengthen the framework. The superleggera tubes were brazed (welded) to shape on a jig and the panels were then fitted over this. The panels are only attached at their edges, mostly by swaging the panel edges over angle-section strips on the steel framework. Most of the panel has no rigid or metal-to-metal contact with the framework, it merely rests on it. Carrozzeria Touring licensed the superleggera construction system to Aston Martin, who designed and manufactured superleggera bodywork for the DB4 and DB5.

2. Major drawbacks/benefits: A superleggera body cannot meet modern impact resistance standards, the cost of manufacture and galvanic corrosion between the aluminum body panels and the steel tubular frame are also issues. As well, the frame tubes used to construct a superleggera body are too small and inappropriately designed for mounting suspension components, so a chassis is required, a disadvantage not found in space frame and other chassis systems. Car makers such as Bristol, were somewhat more successful in countering galvanic corrosion than other manufacturers. Bristol introduced Superleggera construction on the Bristol 401 of 1948.

A ‘superleggera’ type upper structure showing the frame required .

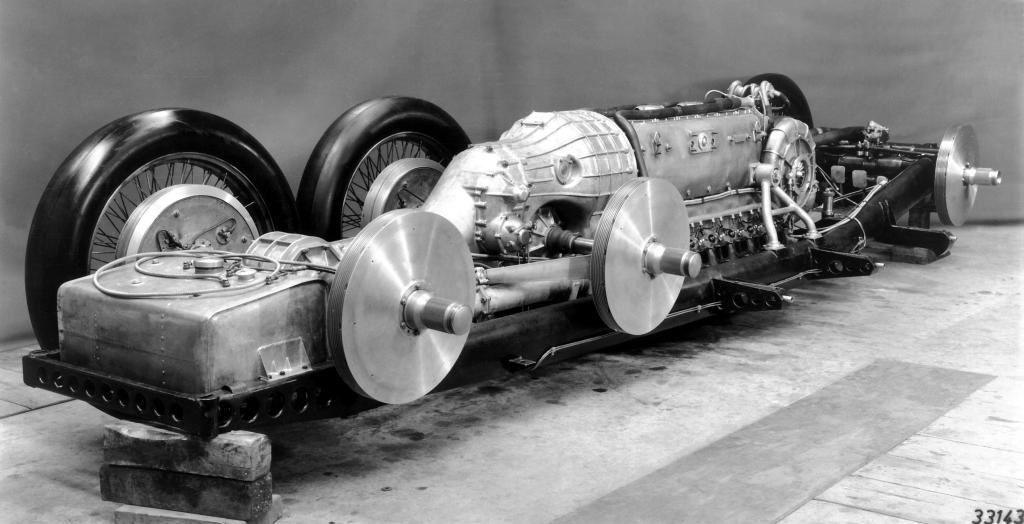

A spaceframe chassis showing suspension attached to the tubes. Note extensive triangulation.

Aside from light weight, the superleggera construction system allows great design and manufacturing flexibility, enabling coach builders to quickly construct innovative body shapes without having to make expensive stamping dies. Good for low volume construction.

3. In order to combat galvanic corrosion the tubes were wrapped in burlap or with a rubber spacer. Aston Martin placed a felt strip between the tube and the body metal which often fell out and when water was present and the materials rubbed, then galvanic corrosion issues began.

DB4 structure showing main frame structure and Superleggera upper section.

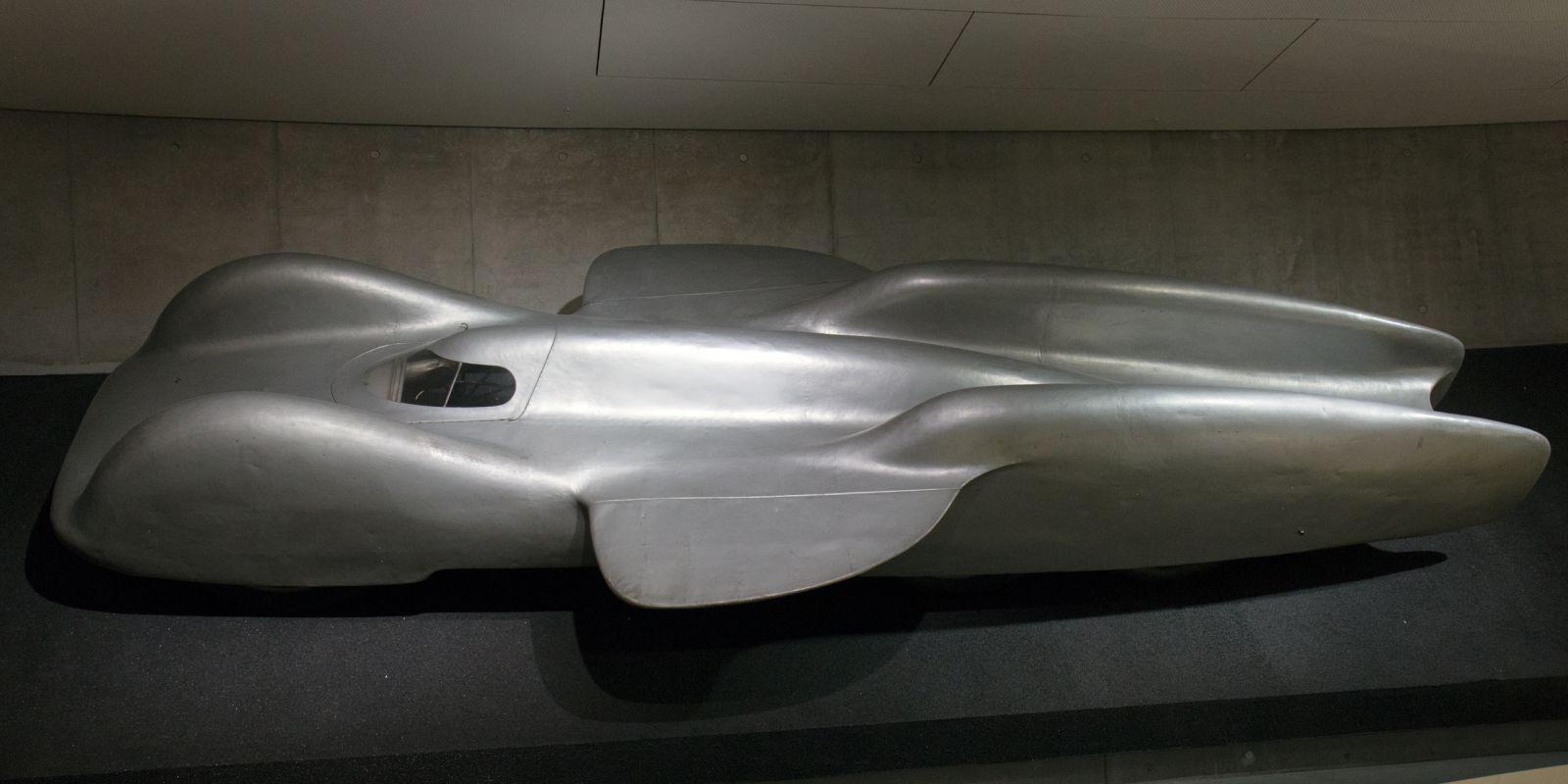

DB4 structure showing main frame structure and Superleggera upper section.4. The car is a Mercedes Benz T80 Rekordwagen. Designed by Ferdinand Porsche. It had some 3,000 HP.

In this picture you can see the massive frame.

And here you see the tubing that the body panels would be draped over.

It never ran as the war intervened.

There, way more than you ever wanted to know!!

-

November 28, 2017 at 1:37 pm #5039

Great explanations! Thanks MiA! :wacko:

The Happy Canadian Scale Modeler!

-

November 30, 2017 at 10:19 am #5046

That is a beautiful Alfa MIA but not the one I was thinking of.

Nor is the Merc the version I was thinking of which was done by Carrera.

Here is a link to the Alfa:

http://www.alfabb.com/bb/forums/alfa-romeo-history/145360-streamliner-6c-2300-a.html

The Recordwagon looks spectacular!

This is the Merc Streamliner I was thinking of:

No doubt it uses the same construction technique.

-

December 1, 2017 at 12:06 pm #5062

I think it was Art who was asking how much support did the body panels have if they were simply ‘draped’ over the tubes. The answer -not surprisingly- is …. sometimes not nearly enough!!

An early shot of the w125 streamliner after a test!! The front is not supposed to look like that!!

-

-

AuthorReplies

- You must be logged in to reply to this topic.

› Forums › Slot Car Paddock › Slot Car Resources › Historical 1:1 › Just for fun